Anton/Bauer is a Videndum brand. The name may not be instantly recognizable to everyone, but anyone that has worked for any length of time in TV or movie production will know the brands it incorporates besides Anton/Bauer.

OConnor, Manfrotto, Sachtler, SmallHD, Teradek, Litepanels, and Vinten, just to name a few.

The company’s roots are as old as the movie business itself. Engineer William Vinten began designing projectors for the budding British film industry back in 1909. Vinten’s ingenuity eventually covered a diverse array of cameras, equipment, and camera support gear – tripods, pedestals, pan-and-tilt heads, and robotics – all of which are still considered industry leaders. The Vinten company continued to acquire top brands in production gear and eventually became Videndum in 2022.

It may be this long history that gives us such a clear sense of the future. The company has first-hand experience of how a company can shape the direction of an entire industry. As a result, we have made our sustainability transformation a priority.

Sustainable production

Our Cartago, Costa Rica factory opened in 1985 as an assembly plant for renowned tripod manufacturer Sachtler. Videndum acquired Sachtler in the 1990s and the facility expanded to become a manufacturing facility for other Videndum brands including Anton/Bauer.

The Costa Rica plant is now a top-tier manufacturing facility, with close to 200 employees, covering 7500 square meters, and now produces 80% in quantity and 65% in value of the company’s products.

Our long-time operation in Costa Rica gives us a head start on other companies as we have already immersed ourselves in a culture and legal framework in which sustainable practice is deeply embedded.

Costa Rica’s approach to sustainability on a national level has been aggressive and world-leading. After having one of the worst deforestation rates in the world, over a quarter of the country is now protected. About half of that area is national parkland available to the public, and the rest is accessible only to indigenous people and researchers. In 1998, the government passed the Biodiversity Act, allowing enforcement of sustainable practices when individuals or companies interact with the country’s priceless biological resources.

In 2019, Costa Rica received the Champion of the Earth award, the UN’s highest environmental honor and in 2022 became the first country to take advantage of the IMF’s new Resilience and Sustainability Facility (RSF), which provides financing to countries trying to reduce risks related to natural disasters.

Our Cartago Factory has earned “Essential Costa Rica” certification, a key international branding initiative. Aligned with the company’s values, the certification process focused on excellence, sustainability, social progress, innovation, and Costa Rican participation, ensuring adherence to rigorous standards in leadership, resource management, environmental responsibility, social progress, innovation strategy, and local workforce involvement.

Decarbonizing energy and travel are the first two sustainability priorities of any business. Videndum aims to be net zero for Scope 1 and 2 emissions by 2035 and for Scope 3 by 2045. While most businesses are still at the mercy of their national energy mixes, Costa Rica’s national electricity production is already approaching zero carbon, with a grid powered by 98% renewable energy – primarily hydroelectric and geothermal.

Proactive power

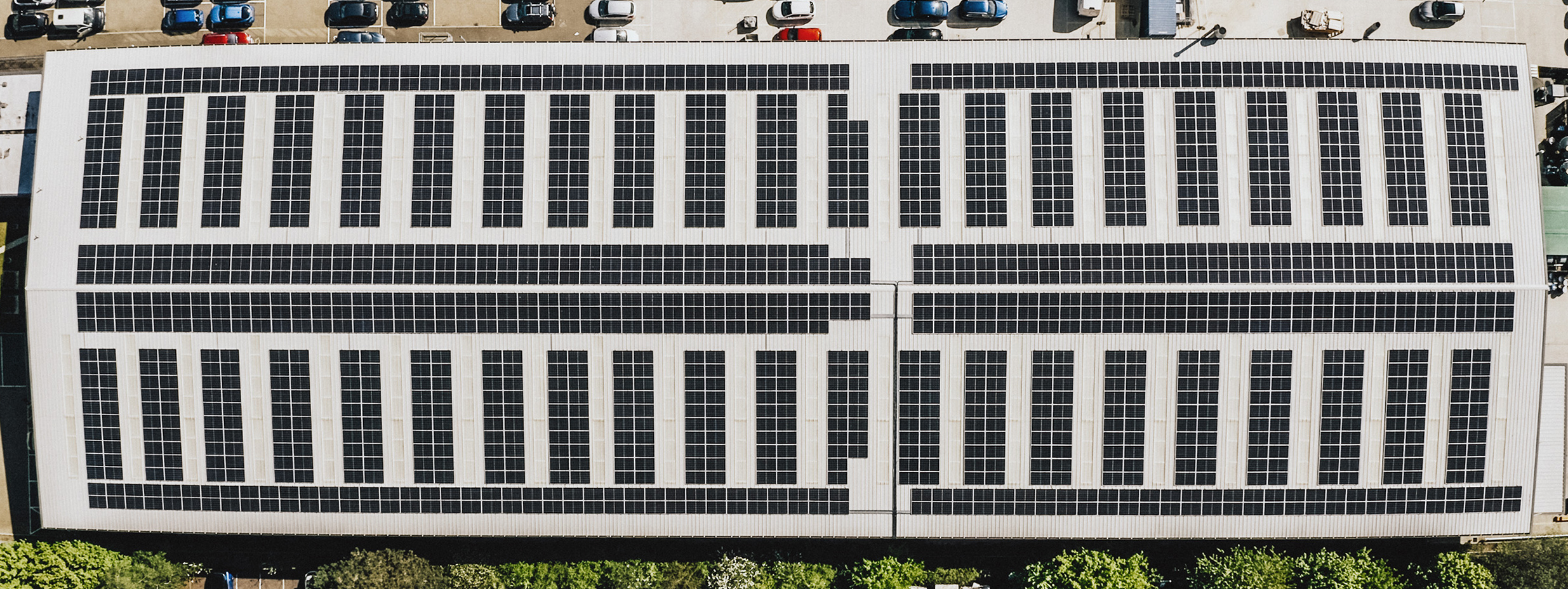

Videndum Production Solutions has its international headquarters in Bury St Edmunds, UK. In contrast to Costa Rica, the UK’s energy mix still leans on fossil fuels, with a little over half of its grid is powered by low or zero carbon sources. But we aren’t waiting for the UK grid to go green. Since March 2022, a solar panel array has powered the Bury St Edmunds factory site. The installed capacity is enough to cover our needs (depending on climate conditions). And for good measure, solar panels have been installed on the Costa Rica plant since January 2022, which will add to the local area’s already green energy mix. This system capacity is the maximum allowed by current regulations and it covers around a third of our electricity demand while saving around 13 tonnes of CO2 per year for its expected lifetime of 25 years.

The upgrade to self-sufficient, zero carbon energy aligns with Videndum’s global ESG strategy. Our energy usage represents a significant proportion of our environmental impact. To promote environmental stewardship and preservation of resources, we monitor and track energy usage across our manufacturing, warehouse, and administrative sites to identify opportunities and implement changes to reduce our energy usage.

The primary motivation to install solar panels at our manufacturing plants in Cartago and Bury St Edmunds was to generate clean energy to power our systems, but there are times in the day when we generate more than we are using, so that excess energy goes back into the grid. Credits received for this excess energy offsets the cost of installation.

We are also reducing our energy usage by switching to LED lighting across all Videndum facilities worldwide. Recently the UK site has focussed on water consumption with the installation of more efficient plumbing and faucets and upgrades to manufacturing processes saving over 6,000 liters of water per year. Other improvements to our production line have reduced waste materials by over 90%.

We are introducing sustainability-focussed design principles into packaging by using biodegradable alternatives to plastic bags, removing glue and adhesive labels, and printing directly onto boxes.

Our factories have also adopted a number of ISO standards around environment. Both the Bury St. Edmunds and Cartago facilities are certified with ISO 14001, which sets out criteria for environmental management systems. The ISO 14001 was first launched in 1996 but revised in 2015 with an update that includes greater focus continual improvement, with environmental management as part of overall business strategy, as well as involvement of business leadership, protection of environment, better communication with stakeholders and greater care in product life-cycle.

The Bury St. Edmunds and Cartago sites are also accredited with ISO 50001, an international standard for efficient energy management, which also aims at continuous evaluation and improvement of energy policy.

Our environmental awareness efforts continually evolve to comply with regulations and to make our business better and more sustainable and to focus on actions that create positive environments in which to work and live.

Sustainability is social

Ensuring that our environmental upgrades are benefitting our people is essential.

Alongside solar panels, we also installed EV chargers in the parking areas at our Cartago and Bury St Edmunds facilities that are free for our employees to incentivize them to choose electric vehicles.

Getting the entire company onboard is essential for a successful strategy. We encourage everyone to become part of the process.

At each of our global sites we have ‘Green Teams’, employee groups who brainstorm ideas, projects and activities that can help better engage everyone around sustainability. Our “Action4Good” program engages employees in environmental, social and governance activity.

For one month each year, using our A4G app, employees record actions they have taken toward certain ESG goals – around health, sustainability or public service. For each hour of time spent toward one of the activities, the company donates money to the Rainforest Trust. Action For Good won the Best Employee Engagement Program at the inaugural Corporate Star Awards in 2023.

The business case

Our journey towards sustainability is more than just a business move – it’s a commitment that stems from our deep industry roots and a desire to shape a positive future. Our certification in global standards, reflect our dedication to excellence, social progress, and environmental responsibility.

We’re not just talking the talk; we’re walking it too. We’re already making strides towards our net-zero emissions goals. But it’s not just about energy – we’re adopting LED lighting, efficient plumbing, and reducing waste across the board

Crucially, sustainability isn’t a top-down mandate; it involves everyone. Our ‘Green Teams’ and “Action4Good” program empower employees to be part of the change. It’s not just about one month of action; it’s a year-round commitment. Participation grows every year because our people believe in making a positive impact.

The Anton/Bauer Salt-E Dog is the first sodium battery designed and built for the motion picture and television industry. Using sodium chemistry, the 9kWh battery delivers consistent, reliable power that is cleaner and more environmentally safe than fossil fuel or lithium generators. With no noise, and no pollution, Salt-E Dog helps productions to deliver on net-zero sustainability pledges and maintain quality standards without compromise.

So, we’re not just in the business of sustainability; we’re in the business of shaping a greener, brighter future, together.